Laser marking

Laser marking is a thermal process in which a high-energy beam of focused laser light is used to change the surface or interior of a transparent material. To do this, the material must absorb the laser light at a certain wavelength in order to change its appearance. From a practical point of view, a laser is a radiation source that emits a narrowly focused beam of light. This laser light is characterized by a characteristic wavelength for the respective laser type and a high power density. The high power density with a small focal spot is particularly important for labeling.

A basic distinction can be made between

Direct marking is often preferred for cost reasons. However, the technological requirements for the marking process are significantly higher here than for marking carriers designed for laser marking.

Principle

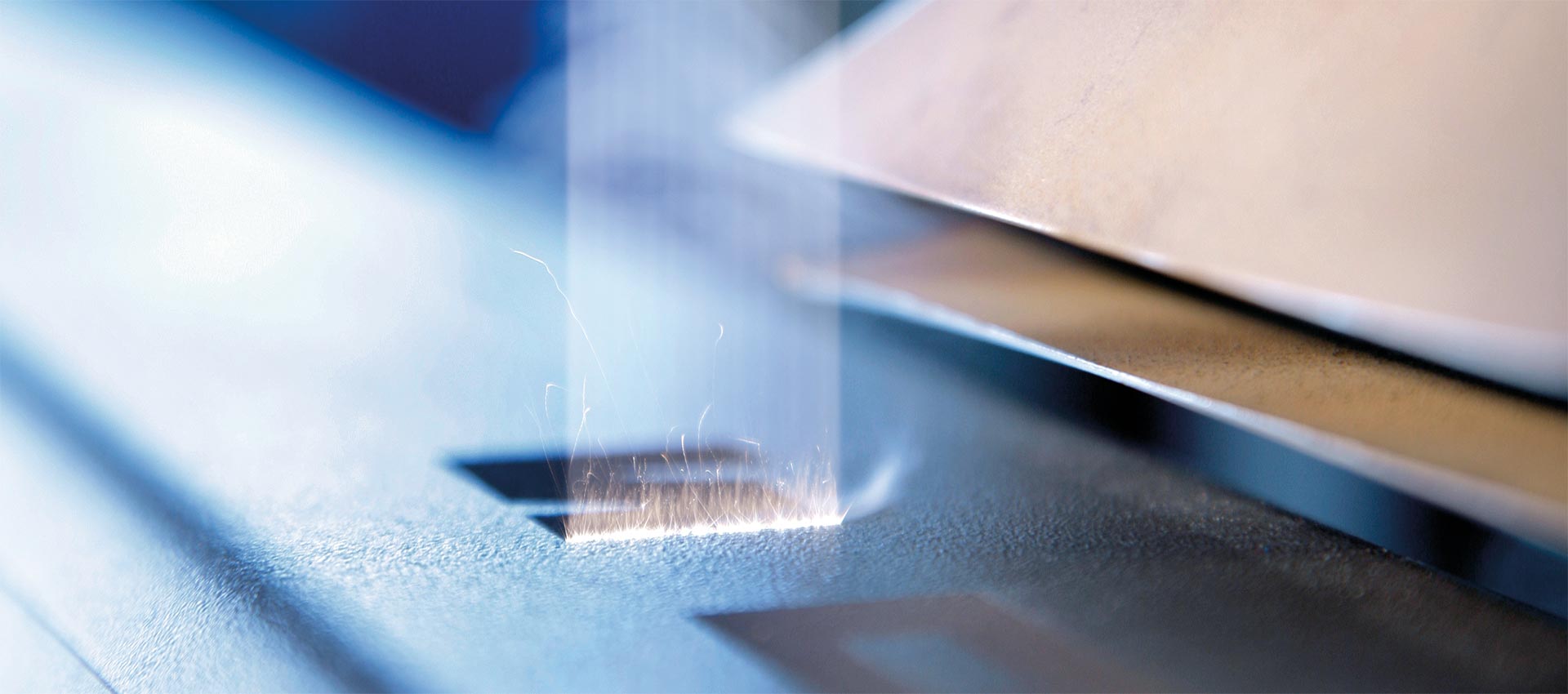

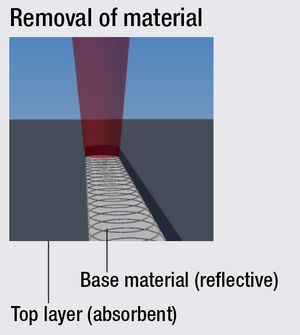

Removal of material

Coated materials can be labeled by removing the top layer with the laser. When removing the top layer of coated (e.g. anodized layers) or painted metals, the laser beam does not interact with the base material, but primarily with the top layer. It is reflected by the base material.

Multilayer plastics can be marked by removing a thin top layer. A typical example of the removal of a coating is the day/night design on control elements.

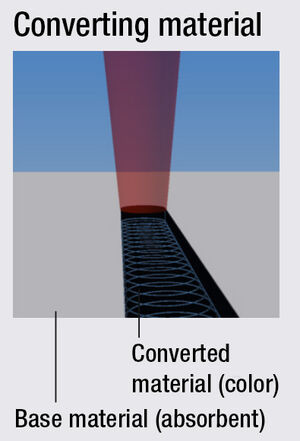

Converting material

Metals, ceramics and some plastics can be engraved with the laser. The power density of the laser beam is so high that the material is partially vaporized within a few nanoseconds during processing.

A depression is created in the material - the engraving. However, the material removal often also changes the color and structure of the surface, making the engraving more visible.

Process Workflow

Laser application

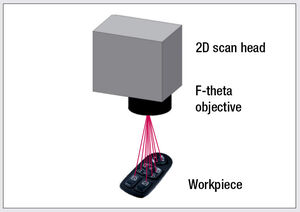

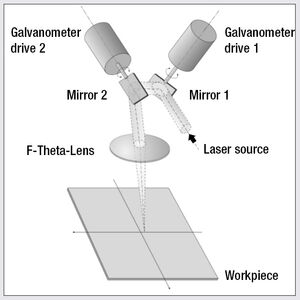

Laser labeling systems consist of four main components:

System description

Two types of laser are available for laser labeling:

Lasers with a wavelength of 1064nm have the largest range of applications. Metals can also be marked at this wavelength.

Fiber laser

Modern fiber lasers are particularly suitable for marking tasks. The advantages are

Fiber lasers are pumped with particularly long-life single emitter diodes.

CO² laser

CO² lasers are not suitable for metals. However, the lower price and lower maintenance requirements make this type of laser interesting for labeling plastics, which fully absorb the laser power at a wavelength of 10640 nm.

This even applies to acrylic glass, which appears transparent to the human eye. CO² lasers from the market leader Synrad are used in Wolf labelling systems.

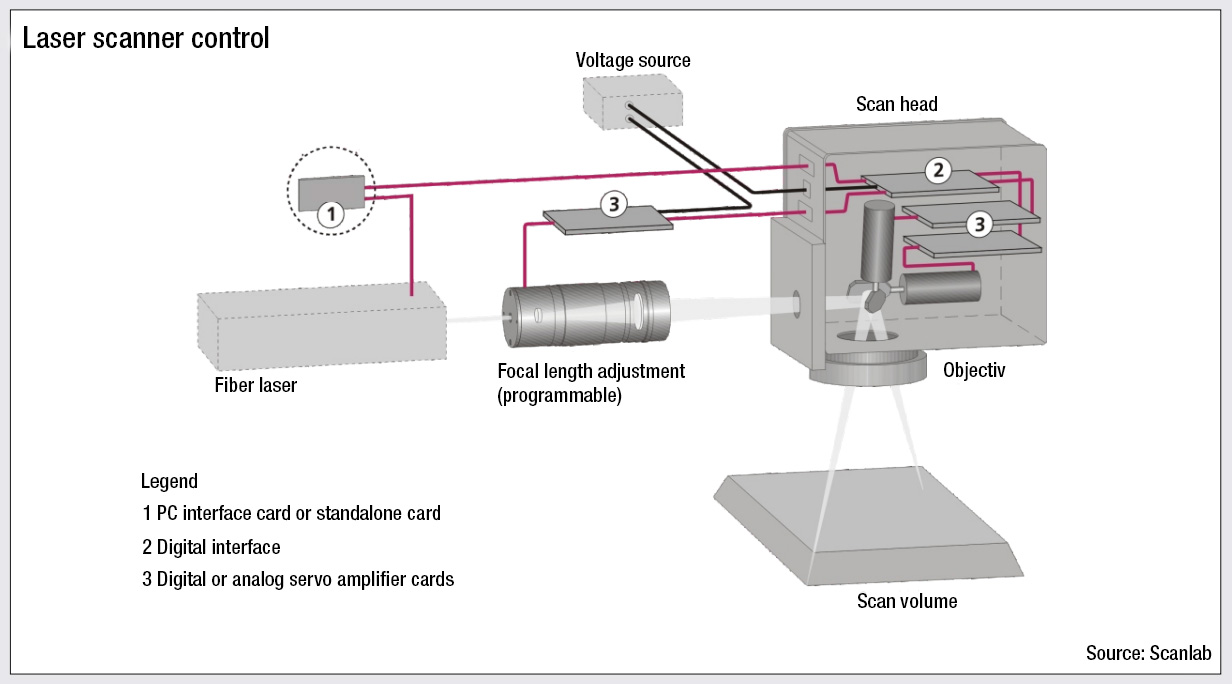

Control system

Wolf laser marking machines are controlled by an industrial PC with Siemens Soft PLC. This PC also controls the laser scanner. The control architecture allows integration into a wide variety of environments. If necessary, additional automatic functions can be controlled. The main control components communicate via:

with each other. This makes the control system easy to expand.

Application